Sustainability & Soluble Oak™

How is Soluble Oak 96% more efficient?

An oak stave is typically cut 33mm thick (in the rough) and there is approximately 5 mm penetration of the alcohol product. ((5mm/33m) – 1 = -.85%)

Given the tight specifications of barrel making, the best-case scenario is that 20 – 25% of the tree fiber is good enough to use for barrel making. (25%)

(5mm/33mm x .25%) -1 x 100 = -96.21%

Soluble Oak effectively extracts from compounds for 100% of the oak fiber.

Conservatively, utilizing barrels to extract oak compounds is at least 96% less efficient when compared to Soluble Oak.

*Oak trees from the time of Napoleon

The Environmental Costs of Tradition

Oak Barrels vs Sustainable Oak

Old Growth Trees

Tree Waste

Conservatively, only 20 – 25% of the White Oak tree can be used for barrel making. Only two 225 liter barrels can be manufactured from the heartwood of a French Oak of 80 – 120 years old. Given the tight specifications for making barrels, most of the log is discarded and cannot be used in making staves. To avoid leakage, a sawyer must cut staves that are clear (without knots) and avoid the cambium (sap) layer. Furthermore, only a certain grain orientation is used (quarter sawn/rift).

Most of the log does not meet the demanding specifications, and ends-ups in low-value products such as railroad ties, low grade lumber, pallets, chipped for fuel, or is used as animal bedding. American White Oak logs are more efficient, but still only a small portion of the tree is used.

Barrel Inefficiency

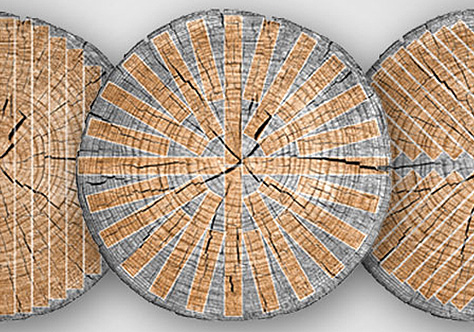

Approximately 80% of the barrel is not used to impart flavor. The above photo shows the penetration into the oak after 10 years. This well illustrates that less than 20% of the barrel is used to impart flavor.

The design of barrels has changed little since their invention by the Celts in 350 BC. Only a small portion of wine/spirits actually comes in contact with oak. Most staves are manufactured at just under 1-1/4” thickness (prior to surfacing).

However, barrel penetration after 4-10 years rarely reaches over a 1/4” depth (and by the 4th year most of the barrel’s extractives have leached). This means, with imparting flavor, 80% of the wood in barrels is completely wasted, and that 80% of the liquid does not even come in contact with oak.

Sustainable Oak

Seeking stewardship of our dwindling old growth oak forest, and using groundbreaking science to reduce the carbon footprint, Soluble Oak offers an environmental solution which doesn’t sacrifice quality. Given the molecular complexity of oak, traditional extraction methods have been substandard.

Please consider the environment & switch to using Sustainable Oak.

- 80% Reduced Carbon Footprint

- 96% more efficient than barrels

- 100% of the oak used is further recycled

- Not dependent on Old Growth Oak

- Ask about becoming an Ultra Sustainable Partner

"The Sustainable Oak® logo on our products is a way to demonstrate our commitment to the environment."

Brendon Townsend - Townsend Cellar

Become an "Ultra Sustainable Partner"

Become the ultimate recycler. Turn your company’s barrels into Sustainable Oak and receive substantial credits on future purchases of Soluble Oak. Committed recyclers can display the “Ultra Sustainable Partner” beneath the “Sustainable Oak” logo on their products (conditions apply).

After your barrels are converted into Soluble Oak, the oak fiber and steel banding are further recycled into other green products.

Sustainable Oak Partners

Ultra Sustainable Partners